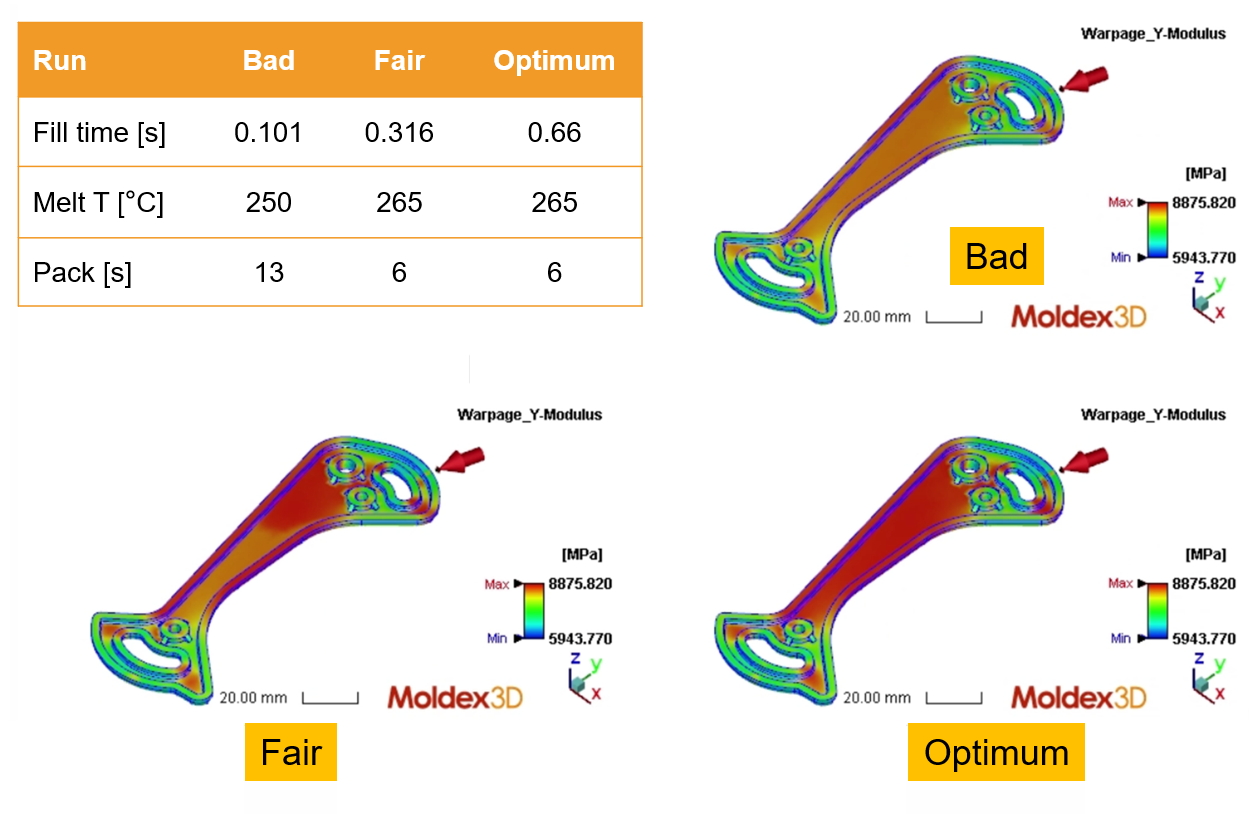

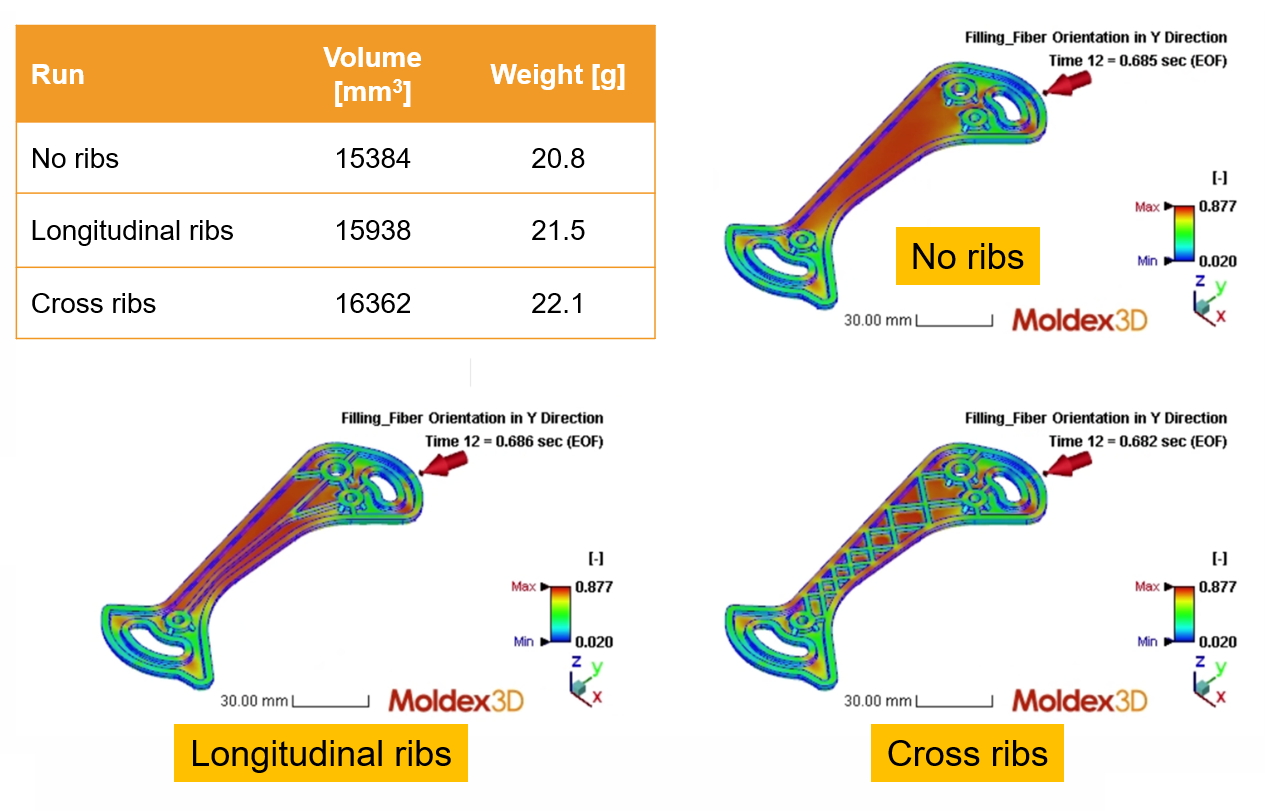

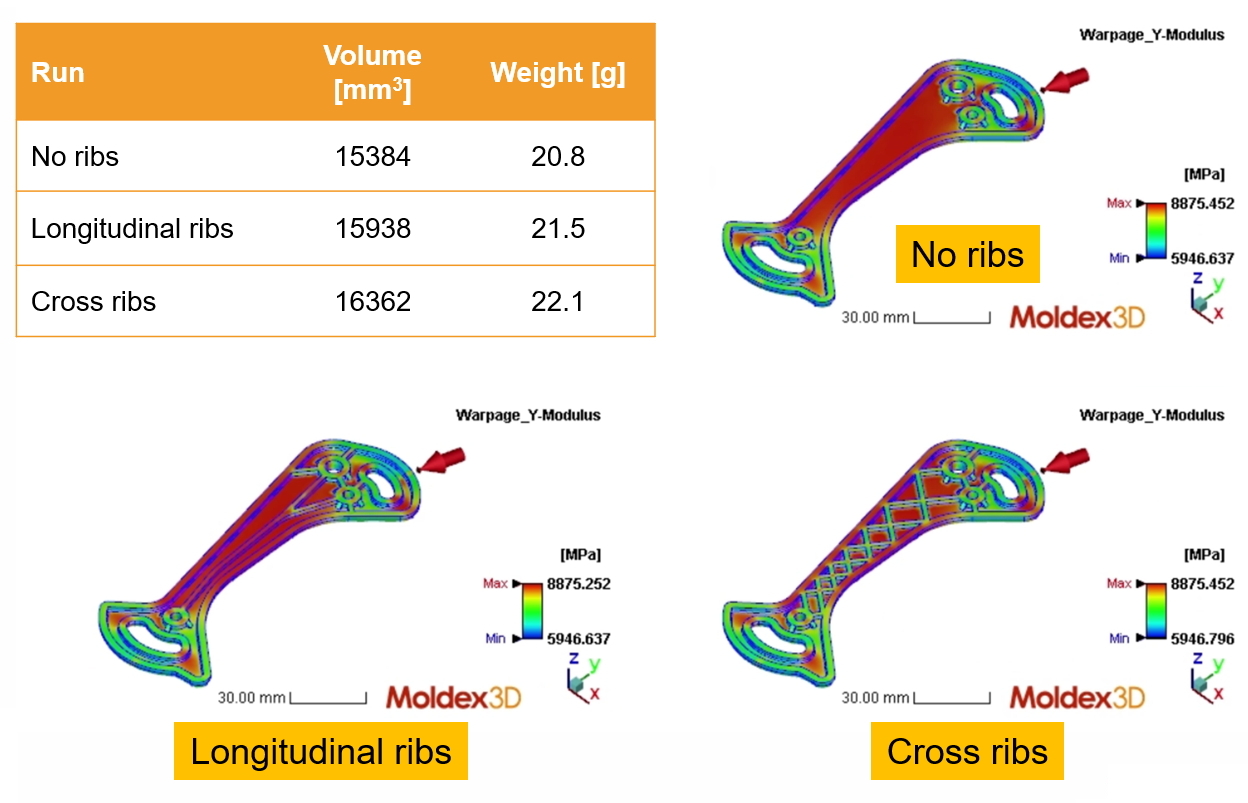

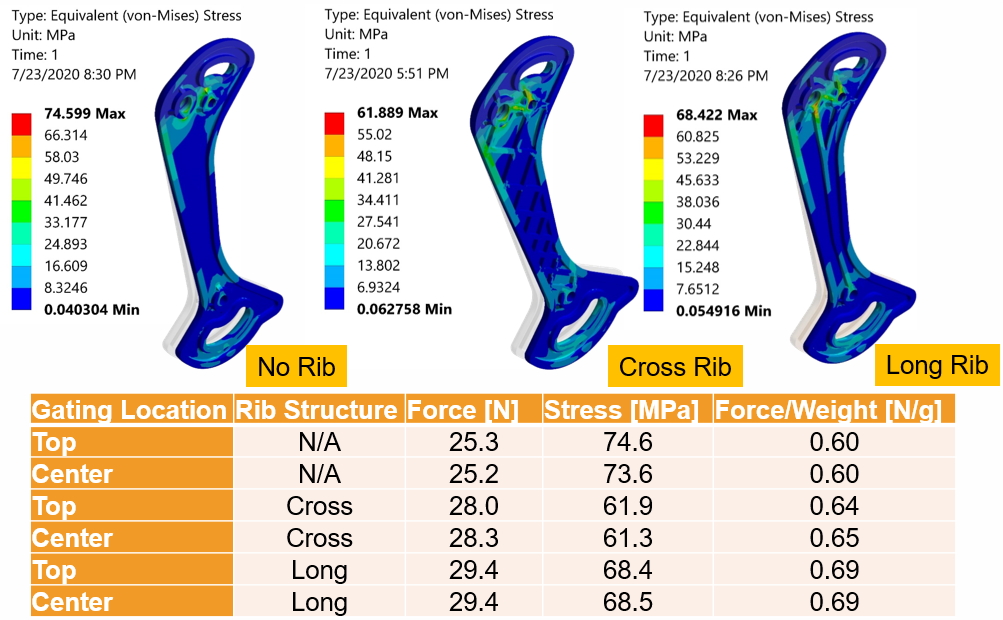

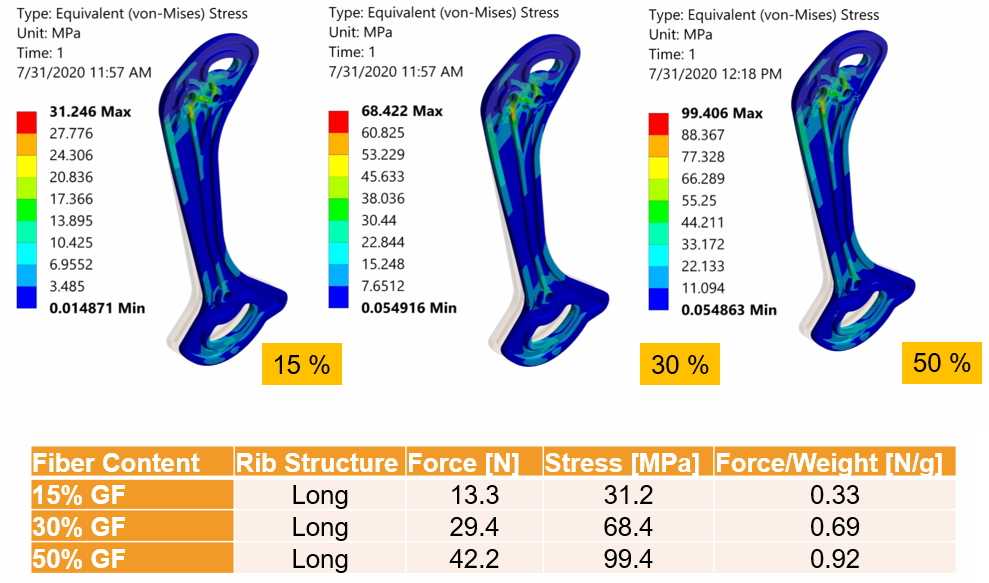

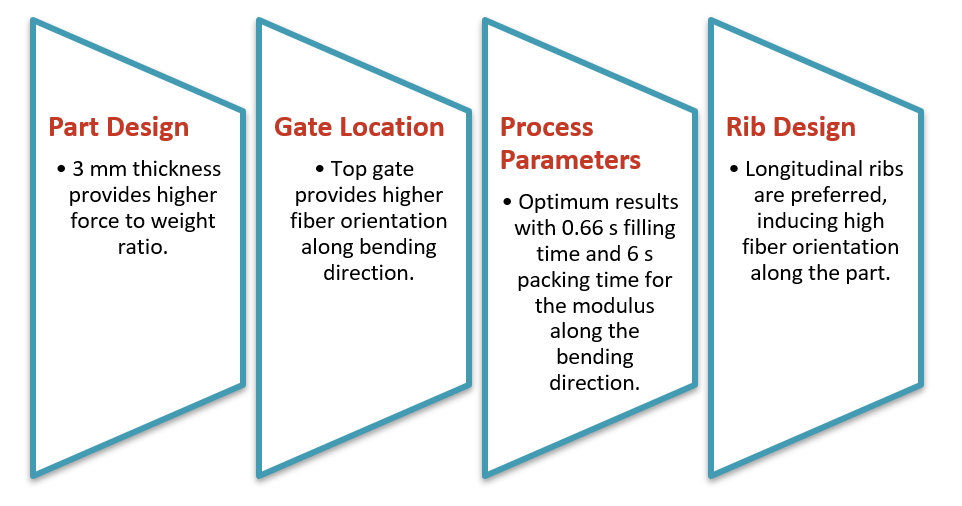

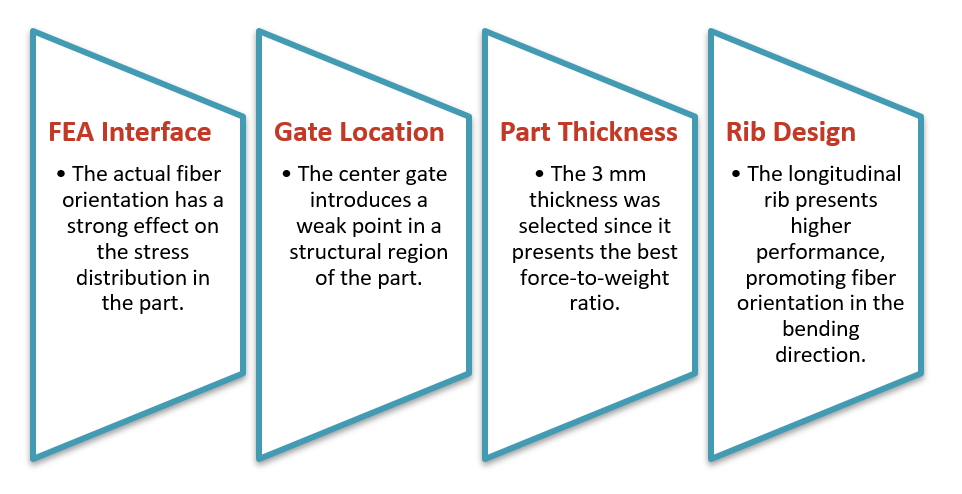

The Plastics Engineering (ESE) program is administered by the Department of Plastics Engineering, UMass, Lowell. Various levels of external support allowed the program to continue its mission of being recognized for excellence in plastics engineering education and research. (Source) Rear derailleurs are the structural components for bike gears (Fig. 1). They are commonly made using either aluminum, steel, or fiber-reinforced thermosets composites. The component is usually an assembly of two metal parts that hold the chain in between. This project proposed to use process and structural simulation to re-design the component for manufacturing with a fiber-reinforced resin. This approach includes re-design and optimization of the part for injection molding, and structural analysis using the CAE results as inputs for the orthotropic material properties. Coupling the process simulation with the structural FEA allow for advanced optimization of part and mold design. The UMass Lowell team used Moldex3D to study the correlation between part design, mold design, fiber orientation, and structural properties. The software was used to validate fiber content and resin selection from a processing and functional perspective. The approach demonstrates the effectiveness of combining process simulation and structural simulation for redesigning products with plastic reinforced polymers. The objectives of this study were to design a structural component using fiber-reinforced thermoplastic to replace metal. The UMass team used Moldex3D to analyze the effects of processing on orthotropic material properties, and tried to optimize the design for manufacturing, considering fiber content, part design and mold design. Then, they validated product design by coupling Moldex3D and FEA software. To achieve desired structural properties, the team proposed several designs with (1) different gate locations, (2) fiber content and (3) the process parameters (Fig. 3). Three different gate locations and other designs were analyzed; the optimum design was defined considering the fiber orientation and the structural properties. The UMass Lowell team tried to optimize the fiber orientation and the elastic modulus using Moldex3D, the results are shown below. (Fig. 4 & 5). They also evaluated three compounds characterized by different fiber contents to tune the mechanical properties. A structural model was developed to analyze the stiffness of the part. The orthotropic material model was exported from Moldex3D and input in the structural model. The part performance was evaluated considering the force-to-weight ratio. The redesigned part shows higher force-to-weight ratio compared to the original metal parts (Fig. 6). Increasing in nominal wall thickness resulted in significant improvement of stiffness. The team found 3 mm was the optimum thickness based on the force-to-weight ratio. Longitudinal and cross rib designs also greatly improved the force reaction. Comparing the designs without ribs, with longitudinal ribs and with cross ribs, they found the longitudinal rib the optimum, triggering a high fiber orientation along the ribs. Greater fiber content allowed for comparable stiffness to the steel and aluminum parts (Fig. 7~10). As a result, they decided the best design was 3 mm with longitudinal ribs and 30% fiber content. The detailed optimized designs and process parameters are shown in Fig. 10 & 11. Using Moldex3D and the Design of Experiment tools, the UMass team was able to explore and compare many design iterations at a low cost. The mechanical properties of a fiber-reinforced thermoplastic could be quantified and optimized starting from the fiber orientation results. Moldex3D Warp module helped to explore if the part can be correctly assembled avoiding costly mold design changes. Through the FEA Interface, the process-related material properties could be used to accurately predict the mechanical performance of the designed part. Exporting of the orthotropic material model was extremely helpful for exploring metal replacement solutions, allowing to overcome the complexity of non-isotropic materials properties. As a leading manufacturer in China, we specialize in the production of high-quality Drainage Emergency Vehicles, with our Pickup Type Drainage Rescue Vehicle standing as a testament to our commitment to excellence. Engineered to tackle urban and natural emergencies with efficiency, our Emergency Drainage Pump Vehicle and Trailed Mobile Drainage Pump Truck are designed to swiftly remove water in flood-prone areas, ensuring safety and restoring normalcy. Our Emergency Drainage Pump Vehicle is a versatile solution, built on a robust pickup truck chassis. It integrates powerful pumps with advanced drainage technology, enabling rapid response to sudden floods. Equipped with a high-capacity reservoir and efficient pumping mechanisms, it can evacuate water from affected areas with speed and precision. The Trailed Mobile Drainage Pump Truck is a game-changer for large-scale operations. Featuring a trailer-mounted design for enhanced mobility, it can be easily transported to various locations. This truck is equipped with multiple pumps, offering unparalleled water removal capabilities. Its modular design allows for quick setup and efficient operation, making it a critical asset in disaster recovery efforts. Both vehicles are engineered to withstand harsh conditions, ensuring reliability in the field. With our commitment to quality, you can trust that our Drainage Emergency Vehicles are built to last, providing long-term support in your emergency response efforts. Join the ranks of satisfied clients who rely on our vehicles to keep their communities safe. Contact us today to learn more about how our Drainage Emergency Vehicles can make a difference in your emergency preparedness and response strategies. Drainage Emergency Vehicle,Pickup Type Drainage Rescue Vehicle,Emergency Drainage Pump Vehicle,Trailed Mobile Drainage Pump Truck Henan Lukewei Road Machinery Manufacturing Co.,Ltd , https://www.lkwmachinery.com

Summary

Fig. 1 Bike rear gear assembly examples

Challenges

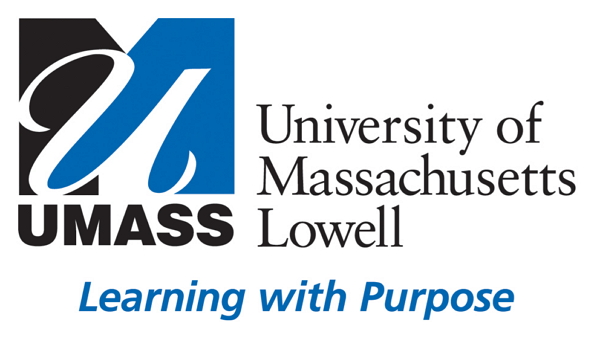

Fig 2. Warpage results of the original design: elastic modulus

Solutions

Benefits

Case Study

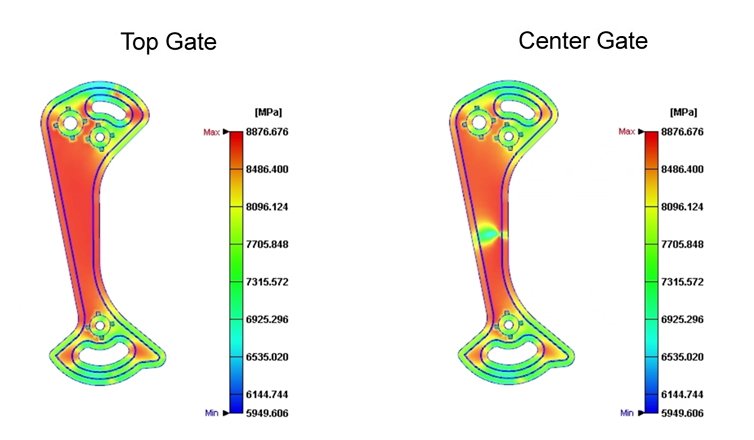

Fig 3. Gate locations and analysis approach

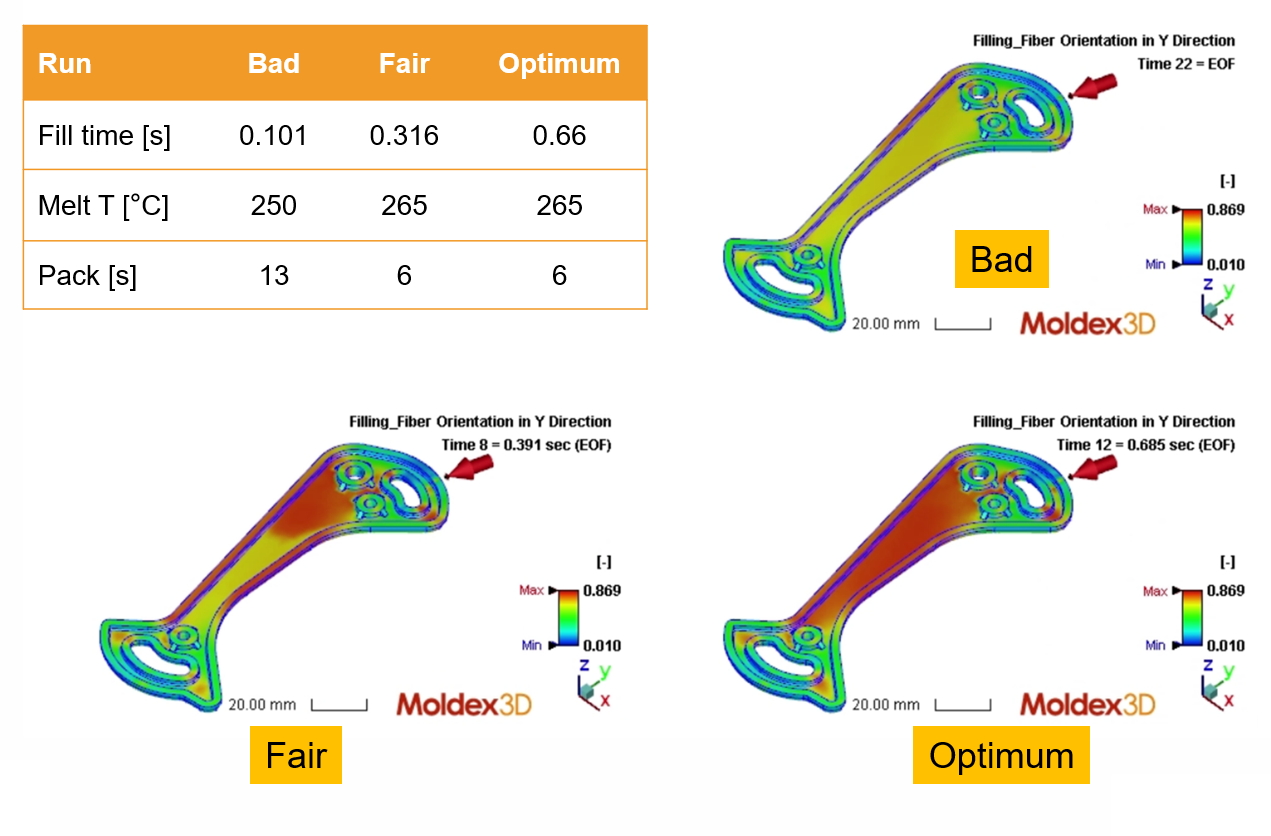

Fig 4. Optimizing fiber orientation by adjusting process parameters

Fig 5. Optimizing elastic modulus by adjusting process parameters

Â

Force [N]

Force/Weight [N/g]

Top Gate

20.7

0.55

Bottom Gate

20.7

0.55

Center Gate

21.0

0.55

Aluminum

43.3

0.74

Steel

40.0

0.62

Fig 6. Structural results

Fig 7. Fiber orientation results of the original and revised designs

Fig 8. Elastic modulus results of the original and revised designs

Fig 9. Structural results of the revised design: influence of ribs

Fig 10. Structural results of the revised design: influence of fiber content

Fig 10. Part and process design using Moldex3D

Fig 11. FEA Interface & structural evaluations

Results

UMass’ Design of a Plastic Bike Rear Derailleur for Metal Replacement

Customer Profile